More Purple!!! I missed out!

November 29th, 2024 | by Peggy Shinn

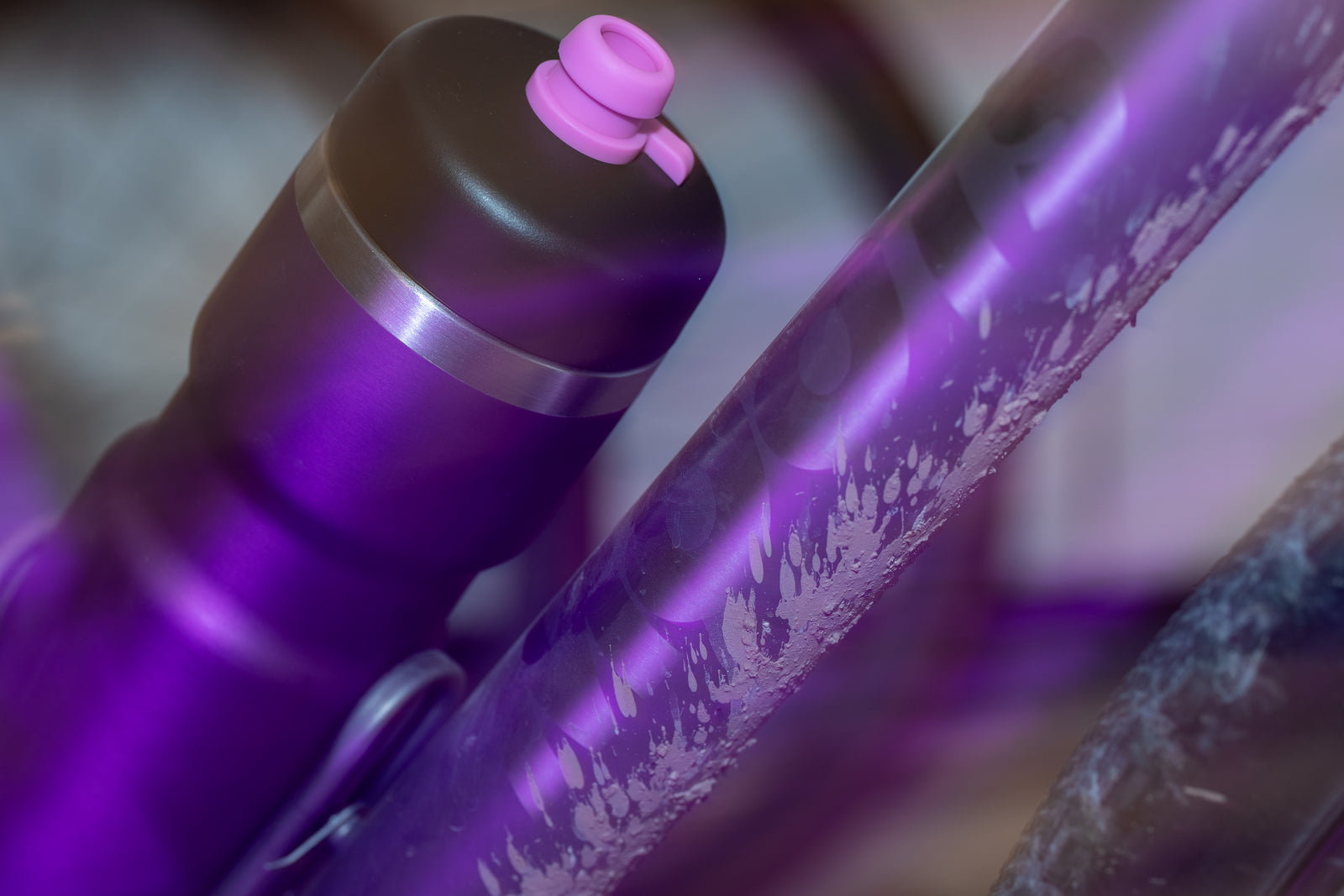

Today, we're launching a brand new Purple Metallic bottle! We made a super limited quantity and each bike water bottle comes with two nozzle options (black and pink) for extra bling.

This bottle is a nod to the anodized metal look so many cyclists love! Why is anodizing the go-to bling for bikes? Peggy Shinn answers this in her piece below on the first-ever bikes, bicycle metallurgy, and anodization techniques. Thanks, Peggy!

Every bike needs bling. Especially my Specialized Epic Evo mountain bike. Its color can best be described as snot. Or more scientifically, phlegm.

To date, I’ve added a Terry Butterfly LTD saddle, Skida fender, Lezyne metallic water bottle cage, anodized aluminum valve stem caps, and have looked with envy at the anodized titanium chain on my husband’s Niner. It’s got this groovy cool sheen that matches the Niner’s (very nice metallic green) paint job.

Bivo bottles definitely give any ride a color pop. But with Bivo’s new Metallic Purple Trio, I’ll be able to have my own groovy cool sheen thing going on.

Bikes haven’t always been so blah on the color spectrum. A quick look at bicycle materials—specifically metallurgy—helps explain how we got where we are, and why adding anodized bike parts to your ride might be a good expenditure.

Today, we're launching a brand new Purple Metallic bottle! We made a super limited quantity and each bike water bottle comes with two nozzle options (black and pink) for extra bling.

This bottle is a nod to the anodized metal look so many cyclists love! Why is anodizing the go-to bling for bikes? Peggy Shinn answers this in her piece below on the first-ever bikes, bicycle metallurgy, and anodization techniques. Thanks, Peggy!

Every bike needs bling. Especially my Specialized Epic Evo mountain bike. Its color can best be described as snot. Or more scientifically, phlegm.

To date, I’ve added a Terry Butterfly LTD saddle, Skida fender, Lezyne metallic water bottle cage, anodized aluminum valve stem caps, and have looked with envy at the anodized titanium chain on my husband’s Niner. It’s got this groovy cool sheen that matches the Niner’s (very nice metallic green) paint job.

Bivo bottles definitely give any ride a color pop. But with Bivo’s new Metallic Purple Trio, I’ll be able to have my own groovy cool sheen thing going on.

Bikes haven’t always been so blah on the color spectrum. A quick look at bicycle materials—specifically metallurgy—helps explain how we got where we are, and why adding anodized bike parts to your ride might be a good expenditure.

Photos from Jody Wilson!

Photos from Jody Wilson!

Baron Karl von Drais from Germany is most often credited as the father of the modern bicycle. In 1817, he sought a patent for a two-wheeled (pedal-less) vehicle dubbed “the running machine” or “swiftwalker” (similar to a modern-day kid’s strider bike). He invented it as a mode of horse-less transportation during an oat shortage. Made of wood, the “Draisine” could be painted, and early images show some models painted, others not.

Riders wanted their feet off the ground, so draisines soon became velocipedes, with pedals affixed to the front wheel’s hub. With wood or cast-iron frames and iron-banded wheels for durability, these contraptions offered a bone-shaking ride—thus their nickname “bone-shakers.” This design morphed into the high-wheeler penny farthing in the 1860s-1870s. Old photos are black and white, so it’s hard to tell what colors these steeds were.

John Boyd Dunlop, a Scottish veterinarian living in Ireland, invented the pneumatic tire, which softened the ride. Around this time, steel tubing found its way into bicycle design (further softening the ride), and the “safety bicycle” became the bike of choice—with both wheels the same size and the device propelled by a rear-wheel pedal-driven chain drive. To prevent corrosion, steel frames were painted.

Then not much happened for almost a century.

Although a few manufacturers dabbled with aluminum bicycle frames in the late 1800s (aluminum becoming commercially available to the public in the late 1880s and 1890s), aluminum frames were not widely available until the 1970s when brands like Vitus and Alan brought them to market. The frames did not have to be painted, making them cheaper to manufacture. While some had a “brushed alloy” finish, others were anodized, giving them an ethereal metallic luster not yet seen in the sport.

Those looking for a lighter, more durable frame material than aluminum could go with titanium. Although the first titanium bike was made in the 1960s—using Cold War technology—the aerospace industry helped refine “ti” into an alloy more usable in bikes. Titanium does not corrode, so frames can be powder coated, bead-blasted, or anodized (thus my powder-coated Zinn). Companies like Moots, Litespeed, Dean, Firefly and Zinn, among others, still make titanium bike frames, and some provide anodized finishes so customers can personalize their rides.

In the past decade, while other materials are still popular, carbon has become the frame material of choice. While carbon frames are lightweight and stiff, let’s face it, they need some dressing up.

Baron Karl von Drais from Germany is most often credited as the father of the modern bicycle. In 1817, he sought a patent for a two-wheeled (pedal-less) vehicle dubbed “the running machine” or “swiftwalker” (similar to a modern-day kid’s strider bike). He invented it as a mode of horse-less transportation during an oat shortage. Made of wood, the “Draisine” could be painted, and early images show some models painted, others not.

Riders wanted their feet off the ground, so draisines soon became velocipedes, with pedals affixed to the front wheel’s hub. With wood or cast-iron frames and iron-banded wheels for durability, these contraptions offered a bone-shaking ride—thus their nickname “bone-shakers.” This design morphed into the high-wheeler penny farthing in the 1860s-1870s. Old photos are black and white, so it’s hard to tell what colors these steeds were.

John Boyd Dunlop, a Scottish veterinarian living in Ireland, invented the pneumatic tire, which softened the ride. Around this time, steel tubing found its way into bicycle design (further softening the ride), and the “safety bicycle” became the bike of choice—with both wheels the same size and the device propelled by a rear-wheel pedal-driven chain drive. To prevent corrosion, steel frames were painted.

Then not much happened for almost a century.

Although a few manufacturers dabbled with aluminum bicycle frames in the late 1800s (aluminum becoming commercially available to the public in the late 1880s and 1890s), aluminum frames were not widely available until the 1970s when brands like Vitus and Alan brought them to market. The frames did not have to be painted, making them cheaper to manufacture. While some had a “brushed alloy” finish, others were anodized, giving them an ethereal metallic luster not yet seen in the sport.

Those looking for a lighter, more durable frame material than aluminum could go with titanium. Although the first titanium bike was made in the 1960s—using Cold War technology—the aerospace industry helped refine “ti” into an alloy more usable in bikes. Titanium does not corrode, so frames can be powder coated, bead-blasted, or anodized (thus my powder-coated Zinn). Companies like Moots, Litespeed, Dean, Firefly and Zinn, among others, still make titanium bike frames, and some provide anodized finishes so customers can personalize their rides.

In the past decade, while other materials are still popular, carbon has become the frame material of choice. While carbon frames are lightweight and stiff, let’s face it, they need some dressing up.

So what’s the best way to dress up and personalize our bikes? Besides strapping a flower basket to the handlebars or lights and beads to the spokes …

Anodized bike parts!

This electrochemical process creates a protective, decorative oxide layer on the metal’s surface. The oxide layer, 1.8 to 30 microns thick, has an iridescent quality that gives bikes and their components that groovy sheen.

(Steel can only be anodized if it is electroplated with aluminum, otherwise the process leads to rust.)

Anodization was first discovered in Japan in 1923 and was used to protect Duralumin seaplane parts from corrosion. It appears that the process was not used in the bike industry until the 1970s when Vitus brought their road frames to market. In 1975, Mavic introduced anodized rims, with silver, gold, and blue wheel sets adorning the peloton. The treatment increased the hardness of the rim walls and protected them from corrosion.

These days, an array of anodized bike components come in a rainbow of colors. With titanium, color is dependent on the thickness of the oxide, which is determined by the anodizing voltage. Like a rainbow, light interference reflecting off the oxide surface and the underlying metal determines the color. Anodized aluminum is immersed in dyes to achieve colors. The parts not only look good, but the anodized layer helps protect them.

So after all this nerdy anodization talk, it’s important to explain that Bivo’s new anodized-looking Metallic Purple bottle is not, in fact, anodized (mostly because anodizing requires the use of toxic acids).

The Metallic Purple bottle is created using a coating that allows light to pass through it, so the metal bottle glistens beneath the paint job. The result: an anodized-like finish.

It’s the perfect way to bling up a blah bike.

So what’s the best way to dress up and personalize our bikes? Besides strapping a flower basket to the handlebars or lights and beads to the spokes …

Anodized bike parts!

This electrochemical process creates a protective, decorative oxide layer on the metal’s surface. The oxide layer, 1.8 to 30 microns thick, has an iridescent quality that gives bikes and their components that groovy sheen.

(Steel can only be anodized if it is electroplated with aluminum, otherwise the process leads to rust.)

Anodization was first discovered in Japan in 1923 and was used to protect Duralumin seaplane parts from corrosion. It appears that the process was not used in the bike industry until the 1970s when Vitus brought their road frames to market. In 1975, Mavic introduced anodized rims, with silver, gold, and blue wheel sets adorning the peloton. The treatment increased the hardness of the rim walls and protected them from corrosion.

These days, an array of anodized bike components come in a rainbow of colors. With titanium, color is dependent on the thickness of the oxide, which is determined by the anodizing voltage. Like a rainbow, light interference reflecting off the oxide surface and the underlying metal determines the color. Anodized aluminum is immersed in dyes to achieve colors. The parts not only look good, but the anodized layer helps protect them.

So after all this nerdy anodization talk, it’s important to explain that Bivo’s new anodized-looking Metallic Purple bottle is not, in fact, anodized (mostly because anodizing requires the use of toxic acids).

The Metallic Purple bottle is created using a coating that allows light to pass through it, so the metal bottle glistens beneath the paint job. The result: an anodized-like finish.

It’s the perfect way to bling up a blah bike.

Thomas Hoover

December 06, 2024

I’d love to have red and burgundy bottles similar to your newly released purple bottle.